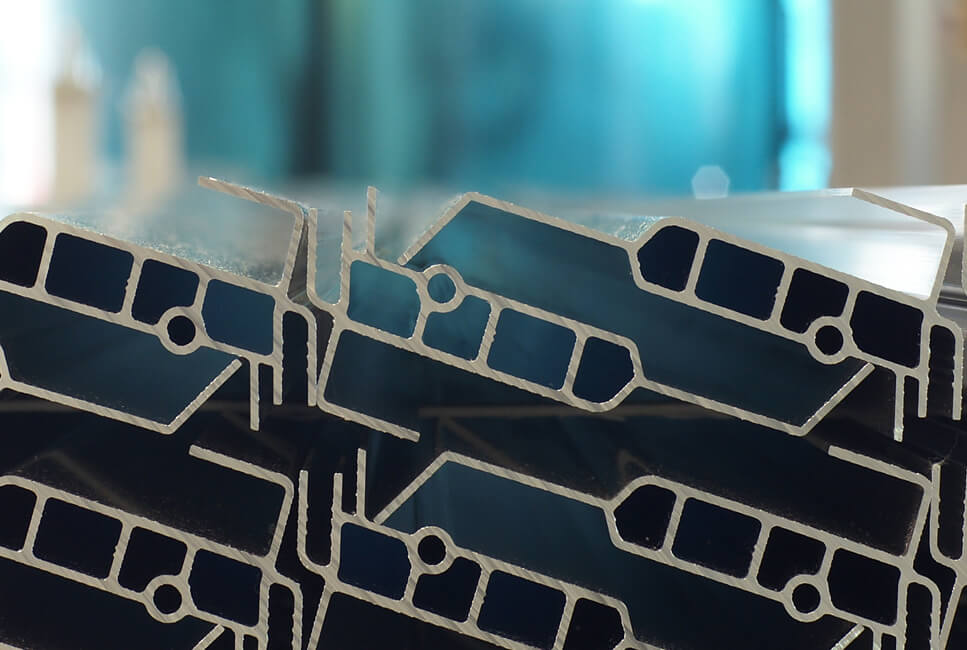

Aluminium

Since 1984, we have been supplying companies, as a volume producer to the German-speaking and Benelux regions, with profiles specially designed to suit a wide range of customer specifications.

Sobald Sie das Video laden, werden Daten zwischen Ihrem Browser und Youtube (Datenschutz) ausgetauscht.

Durch Klick auf den "Play"-Button werden alle Drittanbieter-Inhalte künftig automatisch geladen.

Our Process

All from a single source

At the Thöni Aluminium division, we attach great importance to sustainability, which is why we process scrap into high-grade aluminium components. Thanks to our highly skilled personnel and automated production processes, we are able to guarantee a consistently high product quality.

Thöni supplies everything from a single source, from the idea through to product development and on to product finishing.

We are your competent and reliable partner when it comes to aluminium.

Address

Thöni Deutschland GmbH

Facts and Figures

- Pressure forces of 12.5 MN, 16 MN, 25 MN, 32 MN and 55 MN

- Linear metre weights of 0.15 bis 25 kg

- Profile widths of up to 440 mm

- Profile lengths of up to 12 m

- Alloys: EN AW 6060, 6063, 6005A, 6082

- Customer-specified profiles and products

- Surface treatments such as anodising, pickling passivation and powder coating

- Extensive further mechanical processing possibilities

We will be happy to support you in the technical optimisation of your product.

Are you interested in extrusion products, surface treatment and further processing? Aluminium components from a single source. Just get in touch with us.