Environmental

Energy Engineering

Since 1991, Thöni Environmental Energy Engineering has been developing systems designed to generate bioenergy from organic waste. We put together the best individual solutions for our customers, from planning and construction to service.

Sobald Sie das Video laden, werden Daten zwischen Ihrem Browser und Youtube (Datenschutz) ausgetauscht.

Durch Klick auf den "Play"-Button werden alle Drittanbieter-Inhalte künftig automatisch geladen.

TTV Thoeni Digester

A Unique Biogas Reactor

The TTV Thoeni Plug Flow Digester is ideal for use with organic waste that is dry and has a high impurity content. Its core components are patented; these include the walk-in-accessible heated digester floor and the strongest and most robust paddle agitator in use in the field of high solids AD plants. The TTV Thoeni Agitator is characterised by its ability to perform the complex task of fermenting inhomogeneous substrates uniformly and consistently. The dimensioning of the paddle and shaft is an important factor of mixing efficiency and for ensuring a virtually unlimited service life – even when subjected to very high stress levels. For this reason, the paddle head is specially formed from hard-wearing steel. The special mixer configuration – comprising the design and arrangement of the paddles – allows for 100% prevention of sedimentation, while continually transporting sediments to the digester discharge and at the same time preventing the formation of floating layers. This ensures constant maintenance-free operation of the digester – even when the input material contains very difficult contaminants.

Reliability of every component

The TTV Thoeni Continuous High Solids Anaerobic Digestion (cHSAD) system is characterised by its high level of functionality and ease of maintenance. This is down to our many years of experience in the construction and operation of digestion plants. When we plan a system, we make sure that we install robust plant equipment, including redundant components. This enables us to ensure minimal down times, even when performing servicing and maintenance activities.

How to deal with impurities in organic waste

High impurity rates are no problem for the TTV Digester

The impurities are transported safely along the TTV digester from feeding to extraction. The special design and configuration of the paddles along the shaft prevents sedimentation. That way, potential sediments are continuously transported to the digester exit and have no chance to build floating or sinking layers. This ensures constant maintenance-free operation of the digester all year round.

Sobald Sie das Video laden, werden Daten zwischen Ihrem Browser und Youtube (Datenschutz) ausgetauscht.

Durch Klick auf den "Play"-Button werden alle Drittanbieter-Inhalte künftig automatisch geladen.

TTV Components

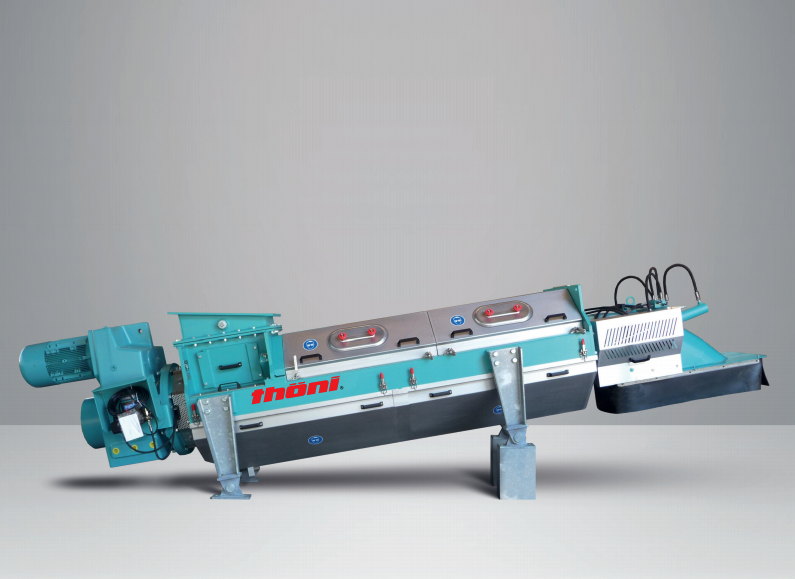

TSP Thöni Screw Press (TSP350-Twin)

-

The TSP Thöni Screw Press (TSP350-Twin) is extremely efficient in the solid-liquid separation in the further processing of digestate-

TSP Thoeni Screw Press (TSP 350-C)

-

The TSP Thoeni screw press (TSP 350-C) is extremely efficient in removing water from the digestates of various compositions and dry material content.

Are you interested in finding out more about TTV Thoeni Continuous High Solids Anaerobic Digestion (sHSAD) system solutions?

TNV Thoeni Agitator

The patented TNV Thoeni Agitator is ideal for ensuring efficient mixing of a wide range of feeds with a very high dry material content. Specially designed paddles keep the material in motion to stop heavy impurities from being deposited on the floor of the digester and prevent potential suspended matter from forming floating layers. This creates ideal conditions in which microorganisms are able to biodegrade the material. The efficient mixing motion means that no further dilution of the digester content with water or by recirculation is needed, with the advantage that less liquid needs to be pumped into the system. It also keeps energy consumption and maintenance costs low.

Flexible waste treatment

Feedstocks with a high dry matter content and a low proportion of impurities are just right for the TNV Digester

Slow-running paddle mixers ensure that the viscous substrate in the TNV Digester is mixed efficiently during digestion process. This largely prevents sinking and floating layers, ensures safe operation as well as low maintenance of the TNV digester for many years.

Sobald Sie das Video laden, werden Daten zwischen Ihrem Browser und Youtube (Datenschutz) ausgetauscht.

Durch Klick auf den "Play"-Button werden alle Drittanbieter-Inhalte künftig automatisch geladen.

Are you interested in finding out more about TNV Thoeni Wet Digestion solutions?

Are you interested in finding out more about our custom solutions? We look forward to hearing from you!